Germany

IEC

Steel Industry

June 2018

Technology used

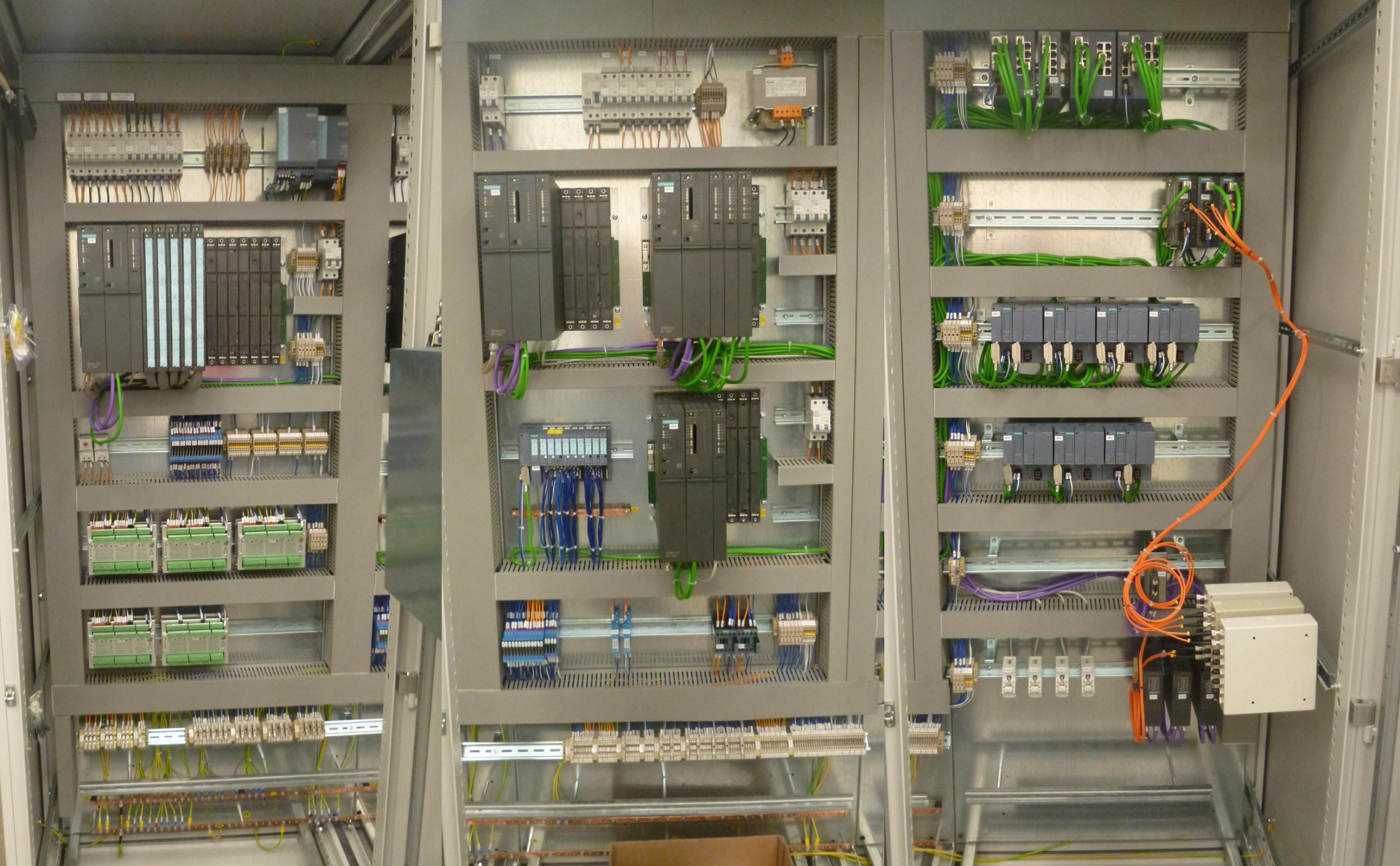

- PLC: Siemens, three CPUs for managing the three plant areas and a Safety CPU for managing the area’s safety

- HMI: Siemens

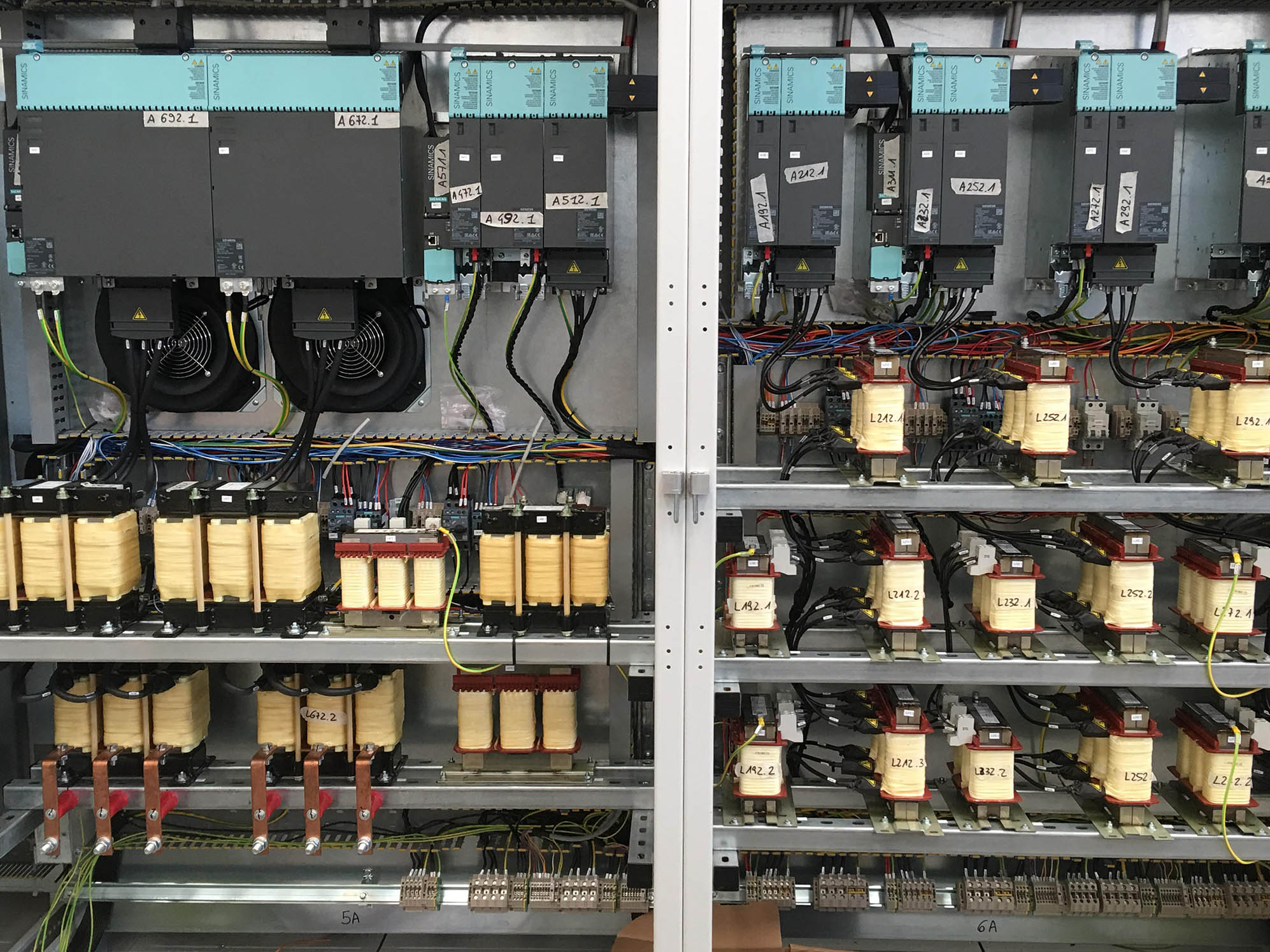

- Drives: Siemens S120 with separate Line and Motor Modules to ensure high performance and flexibility

Rolling lines with cooling bed and finishing line.

This plant is fully made with a Profinet DP protocol to minimise hardwiring.

Management and control of all the steps in the process from the centralised control room above the large plant to ensure a real point of view over the whole line, besides the electronic visibility ensured by the HMI and large monitors.

The aim was to design and manufacture electric devices with DC Bus voltage to minimise the number of wires, save space, reduce costs, increase reliability and recover energy. This was possible thanks to the capacitor batteries on the C.C. Bus, which allow for energy recovery, absorbing and returning energy during every cycle. One single power supply unit is installed between the network and the inverter. If these are connected to DC BUS, they exploit the energy that circulates between inverters, releasing regenerated energy into the network. Moreover, they absorb only the difference in energy required from the network (total voltage absorption of all 450 motors at 7,000 A).